Innovation

We help customers so that they always stay ahead.

By following market trends, listening to our customers, using our common sense and our expertise, we can offer answers and solutions for the challenges facing us all. We do this by carrying out innovation projects and by working on open innovation. For us, open innovation means that we actively participate and collaborate in innovation projects with customers, suppliers, partners, universities and knowledge institutes.

We are convinced of the necessity of innovation for a healthy future.

Our team

Our Research & Development (R&D) department is responsible for developing innovative solutions and for the management of AWL’s product portfolio. We ensure that our customers stay ahead in a world which in the coming years will be dominated by technology, aut

AWL looks ahead

Ongoing automation and digitization are changing the nature of production and logistics processes completely. Consider the explosion of data and new computational capabilities, artificial intelligence, the automated factory, e-mobility and human-machine interaction. These and other production technologies transform every link in the production and logistics value chain – from design to service – and unlock tremendous value for us and our customers. Together with you, we organize R&D programs to allow the development of new technologies and applications in our solutions.

Yes! I would like to know more about your innovative solutions.

Experience Center

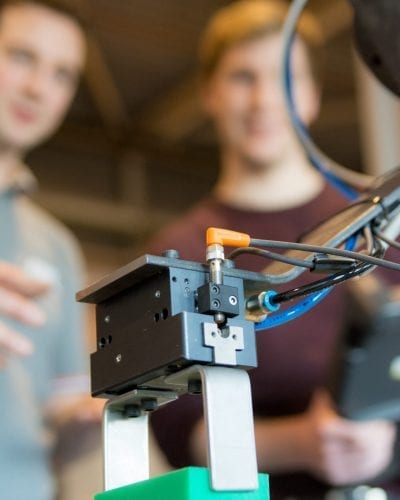

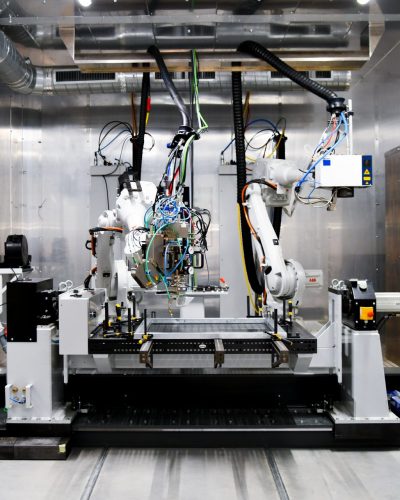

We have an Experience Center, of which we are very proud. The center offers the possibility of creating test assemblies and running trial series and pre-series. Reliable applications are achieved based on the latest technologies. We also use it to carry out welding tests, so that we can validate our customers’ new developments. We thus make it possible to start up new production processes quickly and efficiently.

Moreover, in collaboration with the Fieldlab Industrial Robotics (FIR), we train Robotics Technicians and Robot Engineers here. In addition, work is done in the FIR devoted to developing our own personnel for the future and contributing to social development in preparing the industry for robotization. From Harderwijk, we offer not only schools but also customers the opportunity to develop and experiment with new technologies and applications. The Experience Center is also an ongoing demonstration environment, where you as a supplier can demonstrate technologies to your customers.

Smart industry

Our professionals are convinced that humans will continue to play a crucial role in “smart industry”. In the Experience Center, we are now experimenting with collaborative robots. These robots have been specially designed to work together with humans. Robotization is a human effort.

We have also realized test set-ups for validating developments in the areas of laser welding, resistance welding, arc welding, Vision technology and PLC control technology.

Our innovative projects

OCT

Optical Coherence Tomography (OCT) is a new laser welding quality control method. With OCT it is possible to produce a very fast (> 100 kHz) and accurate distance measurement between welding head and workpiece. This makes it possible to measure the following during laser welding:

- The depth of the keyhole and as such the depth of the laser weld

- The shape of the seam before welding, as input for a seam tracking system

- The shape of the seam after welding, as input for a quality monitoring system

Laser welding with beam shaping

AWL has installed a promising new technology in its Experience Center, beam shaping. We conducted tests using the Trumpf Brightline weld technology. This is a form of beam shaping for laser welding that, rather than making use of only a single focal point, projects a small focal point onto the workpiece in the center of a larger focal point. The advantage is that the small focal point stabilizes the keyhole during laser welding: this makes higher welding speeds possible and reduces weld spatter. AWL has since applied beam shaping in a number of successful customer projects. In-depth research into additional beam shaping opportunities will be conducted in the near future, including the benefits for our customers.

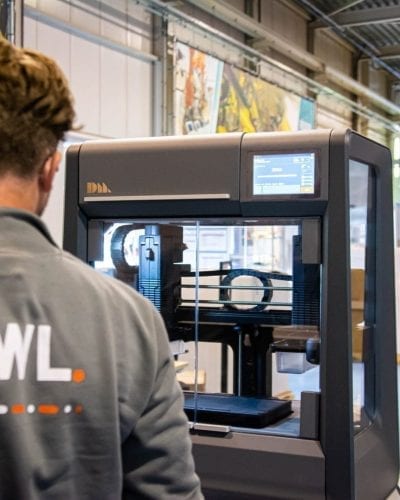

3D metal printing

AWL has gained experience with printing metal components in 3D. We want to use this technology increasingly for the production and integration of complex custom components in our machines. This enables us to offer customization on the one hand, and to deliver machines faster on the other hand. AWL is exploring further options to apply 3D metal printing in its machines.