HI, I'M RODE.

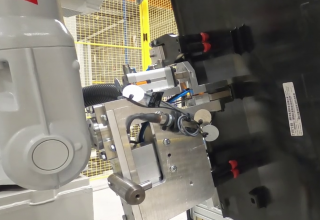

And I empty random mixed pallets day & night.

Nobody should handle dull, heavy items!

Depalletize randomly mixed cases & packages continuously without downtime. Relieve your employees from lifting dull, heavy items and improve your operation’s ergonomics. Our robotic depalletizer (RODE) can handle multiple materials and takes care of obstructions like slip sheets so it can keep going.

Read

''5 Common Mistakes & Misconceptions Made When Starting with a Robot Depalletizer''

Customer Case: Arvato

RODE's Benefits

RODE automatically unstacks arbitrarily-packaged goods such as boxes, bags, or totes from pallets. RODE comes with multiple features like:

- Multi picking.

- Automatic labeling.

- Automatic pallet stacking.

- Automatic ridding of obstruction objects like slip sheets and empty trays to keep the process going.

- And much more…

Want to know more about the specifications of RODE?

Customer Case: DHL eCommerce

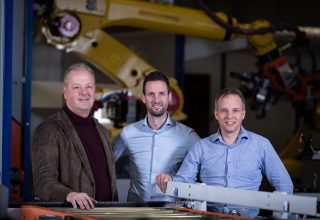

How we will work with you

Close collaboration is critical to understanding your needs and solving any issues you may face. From concept to completion, we are your trusted and knowledgeable partner, as promised and on time.

Let us show you what RODE can do for your business with the tests in our Experience Center. Sign up for a demo below!